In many industrial fields such as chemical,pharmaceutical,and food,

glass lined agitators are widely used as key equipment in various reaction vessels,undertaking important tasks such as mixing,stirring,mass transfer,and heat transfer.Its performance and quality directly affect the efficiency of the reaction,the quality of the product,and the safety of production.What does a High quality enamel glass lined agitator look like?Below we will provide a detailed introduction.Please stay tuned!

The enamel layer of a High quality enamel glass lined agitator is its core protective layer,which directly determines the corrosion resistance of the mixer.Excellent enamel glaze should have a uniform chemical composition and good stability.Among them,silicon dioxide is the main component,and its content and purity play a key role in the hardness and wear resistance of the enamel layer.High purity silica can form a dense structure,effectively resisting the erosion of various corrosive media such as acids,alkalis,and salts.In addition,other components in the glaze,such as borax and sodium oxide,also need to be proportioned to ensure that the enamel layer can melt evenly during high-temperature firing,tightly bond with the metal substrate,form strong chemical bonds,and thus have good adhesion and impact resistance.

The metal substrate of the agitator is usually made of carbon steel or low-alloy steel,and its quality directly affects the strength and stiffness of the agitator.The High quality enamel glass lined agitator substrate should have good mechanical properties,such as high strength,high toughness,and good weldability.The chemical composition of steel needs to be strictly controlled to reduce the content of harmful elements such as sulfur and phosphorus,in order to avoid defects such as cracks during welding and use.At the same time,surface treatment of the metal substrate is also crucial.Strict rust removal,degreasing,and other treatments should be carried out before enamel firing to ensure a clean and smooth surface,providing a good foundation for the adhesion of the enamel layer.

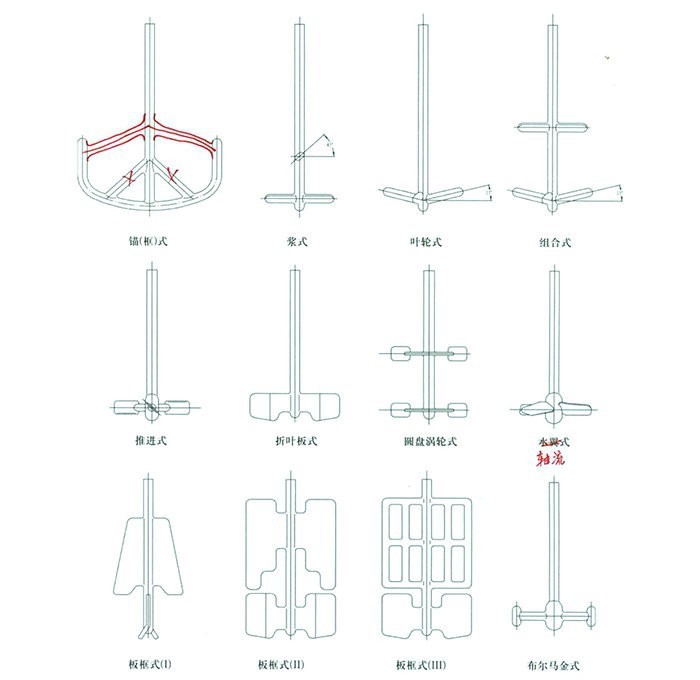

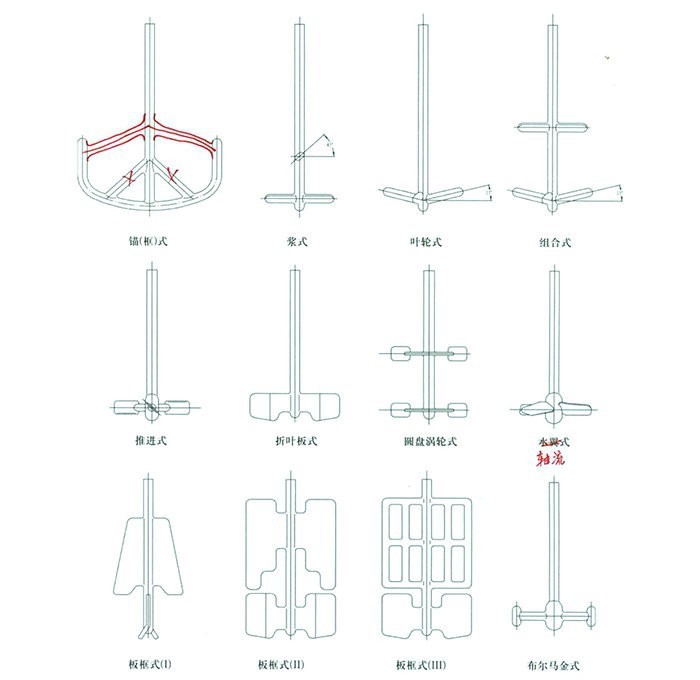

The molding process of High quality enamel glass lined agitator requires strict requirements.The shape and size of the blades of the mixer need to be designed according to the specific reaction process and material characteristics to ensure optimal mixing effect.During the molding process,advanced molds and processing equipment should be used to ensure the dimensional accuracy and surface quality of the mixer.For example,the blades of the mixer should have uniform thickness and smooth surface to avoid defects such as burrs and cracks,which not only affect the mixing efficiency but may also cause damage to the enamel layer during operation.

Enamel firing is the core process in the manufacturing of enamel glass mixers,which directly determines the quality of the enamel glass layer.The enamel burning process needs to be carried out under specific temperature,time,and atmospheric conditions.The temperature control should be within±10℃.If it is too high,it will cause the glaze to flow,the enamel layer to become thinner or even perforated.If it is too low,the glaze will not fully melt,and the adhesion of the enamel layer will be poor.The firing time should also be adjusted reasonably according to the size and shape of the mixer to ensure that the glaze fully reacts with the metal substrate and forms a strong bond.In addition,the atmosphere inside the enamel furnace should be stable to avoid the impact of high or low oxygen content on the quality of the enamel layer.High quality enamel firing process can make the enamel glass layer uniform,dense,and free of defects such as bubbles and cracks.Its thickness should comply with relevant standards,generally between 0.8-2.0mm.

During the high-speed rotation of the mixer,if there is a dynamic imbalance,it will generate significant vibration and noise,which will not only affect the mixing effect,but also accelerate the wear of the equipment,and even lead to equipment damage.Therefore,high-quality glass lined mixers must undergo strict dynamic balance testing and calibration after manufacturing is completed.By using professional dynamic balance detection equipment,the vibration of the mixer at different speeds is measured,and then calibrated using methods such as grinding and balancing to control the dynamic imbalance of the mixer within the allowable range,ensuring its smooth and reliable operation.

A High quality enamel glass lined agitator should have good stirring effect,which can fully mix the reactants,improve the reaction rate and product quality.The evaluation indicators for mixing effect include mixing power,mixing speed,mixing time,etc.The mixer should be selected reasonably based on the volume of the reaction vessel,the viscosity,density,and other parameters of the material to ensure that uniform mixing of the material can be achieved in a short period of time under appropriate mixing power and speed.For example,in the mixing process of some high viscosity materials,the mixer should have sufficient shear force to break the agglomeration state of the materials,promote the dispersion and mixing of the materials.

The mixer should remain stable during operation,without significant vibration or noise.Stable operational performance can not only improve the service life of equipment,but also ensure the safety of the production process.The bearings,seals,and other components of the mixer should be selected from high-quality products and undergo strict assembly and debugging.Bearings should have good lubrication performance and wear resistance,and be able to withstand the axial and radial loads of the agitator during operation.The sealing components should be able to effectively prevent material leakage,avoid environmental pollution and equipment damage.

High quality enamel High quality enamel glass lined agitator should be able to adapt to various working conditions,such as different temperatures,pressures,corrosive media,etc.In high temperature,high pressure,and strong corrosive environments,the enamel layer and metal substrate of the mixer should maintain stable performance,without deformation,cracking,corrosion,and other phenomena.For example,in some high-temperature reactions,the agitator should be able to operate stably for a long time at temperatures above 300℃;In the stirring process of some highly corrosive media,the enamel layer of the agitator should be able to resist the erosion of the medium and ensure the service life of the equipment.

High quality enamel High quality enamel glass lined agitator require excellent materials,exquisite manufacturing processes,performance,and strict quality testing and certification.Only by meeting these conditions can the mixer operate stably and reliably in various complex industrial environments,providing users with effective and excellent mixing services,ensuring production safety and product quality.When choosing a glass lined mixer,enterprises should consider these factors comprehensively and choose suppliers with good reputation and strength.

Address:Zibo City, Shandong Province

Address:Zibo City, Shandong Province WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com